“Design is a way of life, a point of view. It involves the whole complex of visual communications: talent, creative ability, manual skill, and technical knowledge. Aesthetics and economics, technology and psychology are intrinsically related to the process. Design is the evolution of useful things.”

When Paul Rand made this comment he was referring to two books written by Henry Petroski: The Pencil and To Engineer Is Human, in which basically he talks about how we can take everyday objects and turn them into better useful objects. For instance, how pins were turned into paper clips; how Styrofoam containers evolved; how Post-it Notes came about and even how a simple rock can be turned into something very useful. The list goes on and on, and it is easy to understand the connection between Petroski’s points of view with Rand’s ideas on invention, innovation and ingenuity.

When it comes to the evolution of useful things, the oil and gas industry has many examples, but just let’s take this moment to talk about one of them: cementing and its development process.

Cement fills and seals the annulus between the casing string and the drilled hole. It has three general purposes:

- Zone isolation and segregation

- Corrosion control

- Formation stability and pipe strength improvement.

Cement forms a very strong and impermeable seal from a thin slurry. The properties of the cement slurry and its behavior depend on the components and the additives in the cement slurry.

The cement is produced from limestone and either clay or shale by being roasted at 2600 to 3000°F. This high temperature fuses the mixture into a material called clinker cement. Once the roasting step is done, the rough clinker product is ground to a size specified by the grade of the cement. The final size of the cement particles has a direct connection with how much water is required to make the slurry without producing an excess of water at the top of the cement or in pockets as the cement hardens. However, not all cements, including those made from the same components, will have the same reaction when mixed with water. Generally, the differences are in the quality of the grind of the cement, impurities in the water and in the additives added during the cement manufacturing process.

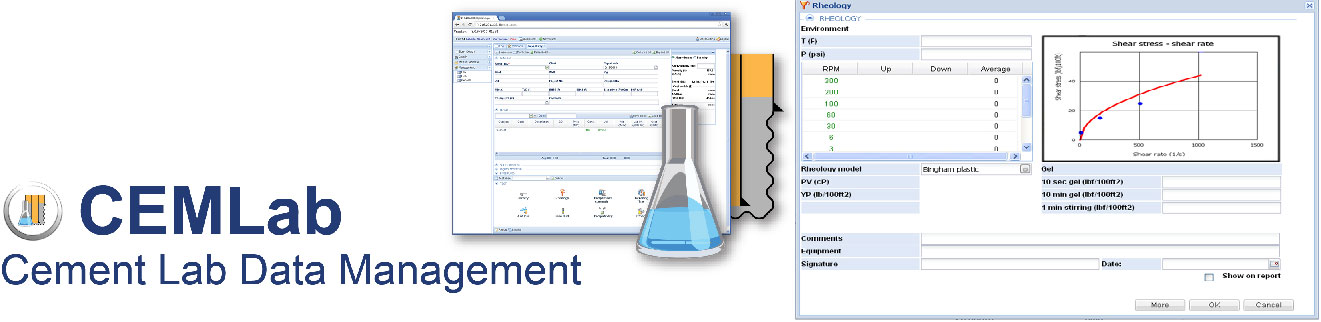

The design and test of the slurry are essential parts of every cementing job and without an efficient lab database cementing companies can face many problems, but thanks to the evolution of technology PVI has developed the right tool for this: CEMLab (Cement Lab Data Management).

Since its first release in the fall of 2012, CEMLab has evolved into a powerful web-integrated and highly functional software product. CEMLab formulates slurries, calculates the amount of all ingredients, generates weight-up sheets and lab reports and allows engineers to have quick access to all their slurry formulation, and testing statuses anytime from anywhere. These are just a few of the many features that make up CEMLab. Just like from the books “The Pencil” to “To Engineer Is Human” we get to see how an object can be designed and turned into something more useful and successful, CEMLab has been turned into a useful, successful and sophisticated lab tool.