With the help of computer modeling, centralizer placement optimization becomes easy to perform for all types of wells. Ideally, this kind of optimization should be done before every casing job. Here is an example of centralizer placement optimization using the CentraDesign software.

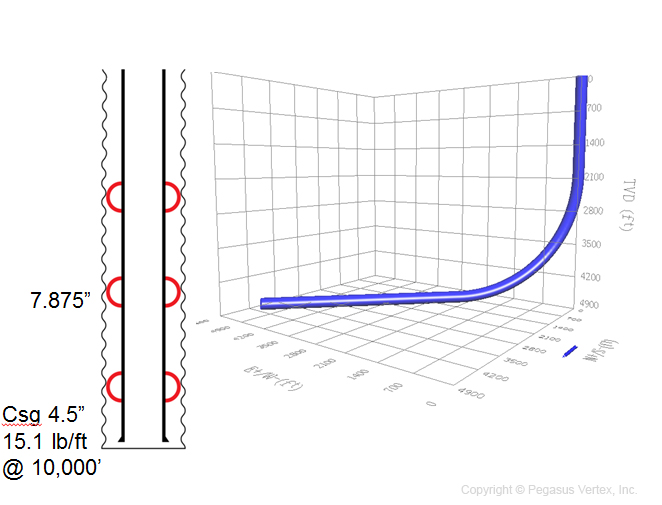

The example well has a kick-off point at 2,000 ft. The previous casing (ID = 8.535”) was set at the same depth. Our goal is to centralize the 12,345 ft of 4 1/2” casing, deviated from 0o to 90o. The centralizer considered is the bow spring type with a restoring force of 800 lbf.

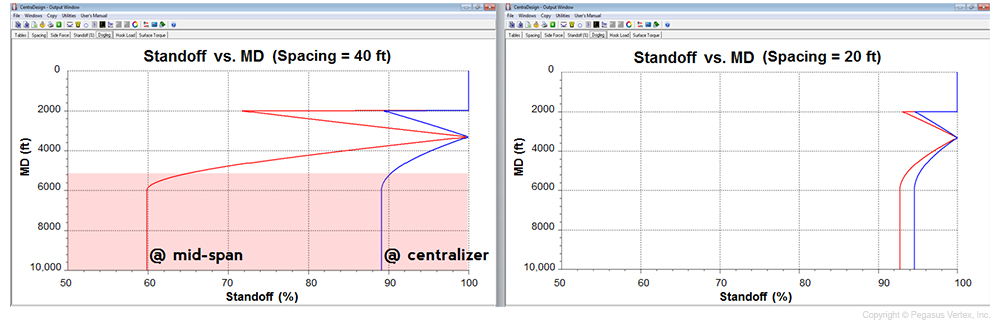

One approach to centralizer placement optimization is to specify the spacing using our experience and knowledge, and then let the software check if it yields a satisfactory standoff profile. We compare 2 cases: one with 40 ft (1 centralizer per joint) and the other with 20 ft (2 centralizers per joint) for the centralizer spacing. Fig. 2 shows the resulting standoff profiles. The blue line is the standoff at the centralizer, while the red line is the standoff at the middle point between centralizers, which is always lower than that of at centralizers. Since we are using the bow spring centralizers, the standoff at the middle point between centralizers is the summation of the casing sagging between centralizers and the bow spring compression at the centralizers.

For centralizer spacing of 40 ft, the number of centralizers required is 251. From 2,000ft to 7,000 ft (deviation from 0o to 30o), the standoff is between 100% and 70%, which meets the minimum industry standard of 67%. From 7,000ft to 12,345 ft (deviation from 30o to 90o), the standoff drops from 70% to 20%, which is problematic: poor standoff profile at this section may cause potential cementing problems.

The natural way to solve this problem is to try 2 centralizers per joint (spacing of 20 ft). The new standoff profile is much better than the normal industry standard, but with the doubled number of centralizers, this new approach may be too conservative, leaving engineers wondering: am I using too many centralizers?

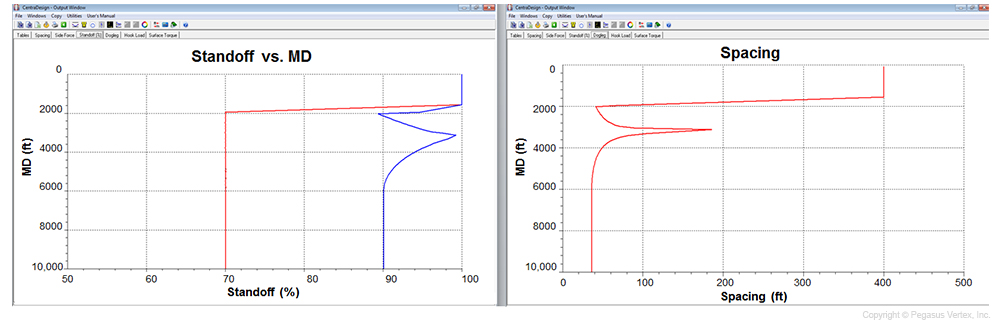

Alternatively, we can specify the required standoff and let the software tell us how to space each centralizer. With the required 70% standoff throughout a 4 1/2” casing, CentraDesign displays the spacing necessary to achieve the specified standoff, as shown in the following figures. The total number of centralizers used is 200, a significant reduction from previous approaches.

Logically, as the well builds up from a 0o to 90o inclination angle, centralizer spacing decreases: casing needs more support in the deviated or horizontal sections. More advanced approach is to combine the “Specify spacing” and “Specify standoff” modes to yield the simple-to-install centralizer placement, yet satisfying standoff profile, by using incremental spacing options. Optimized centralizer placing not only produces good standoff, but also increases the efficiency of field installation of centralizers and avoids the excessive use of unnecessary centralizers.