American writer and best-selling author Denis Waitley said:“Life is inherently risky. There is only one big risk you should avoid at all costs, and that is the risk of doing nothing.”

Risks are everywhere. I was watching a documentary on earthquakes and hurricanes and it got me thinking about how there are risks in everything that surrounds us, but that doesn’t stop us from improving and moving forward. We have to acknowledge that risks exist. Taking risks is in our human nature and when something goes wrong we work towards being more prepared in the future.

Some people are reluctant to take risks because they’re somewhat afraid, but the reality is that taking risks can:

- Open people up to new challenges and opportunities.

- Empower people to establish new limits in their minds.

- Stimulate people to become more creative.

- Result in positive outcomes.

- Help people to clearly define what they’re trying to achieve.

- And once they have become accustomed to taking risks, they break free from the average way of thinking.

In the drilling industry every step and every decision has to be made, yet it is necessary to drill for oil. As a nation on the wheel, the usage of petroleum has become an everyday thing not only for the United States but for the rest of the world as well. So basically it’s all about risk control for every aspect of life including the drilling industry, and in this case it is all about a well done cementing job.

For drilling engineers, cementing seems to be more of an art than a science or technique. Cementing is the process of displacing cement to the annular space between the well-bore and casing or to the annular space between two successive casing strings. With the latest technologies and analytical software such as CentraDesign and CEMPRO developed by PVI, cementing engineers can use these types of software to ensure a complete and proper cement displacement.

A successful cementing job is one of the most important factors in the productive life of any well. However, challenges are always coming along as the wellbore goes deeper and to the places that are harder to reach. It’s already prevalent to predict a cementing job by computing the downhole temperature and pressure. If the cementing job is well done, all the risks are under control; a longer life of the wellbore and a higher productivity is promised.

We are living in a world where technology is advancing quickly. As PVI developers we are trying our best to develop more advanced software to meet the new needs. That’s why we developed CEMPRO+, the ultimate enhanced version of PVI’s mud displacement model, CEMPRO®.

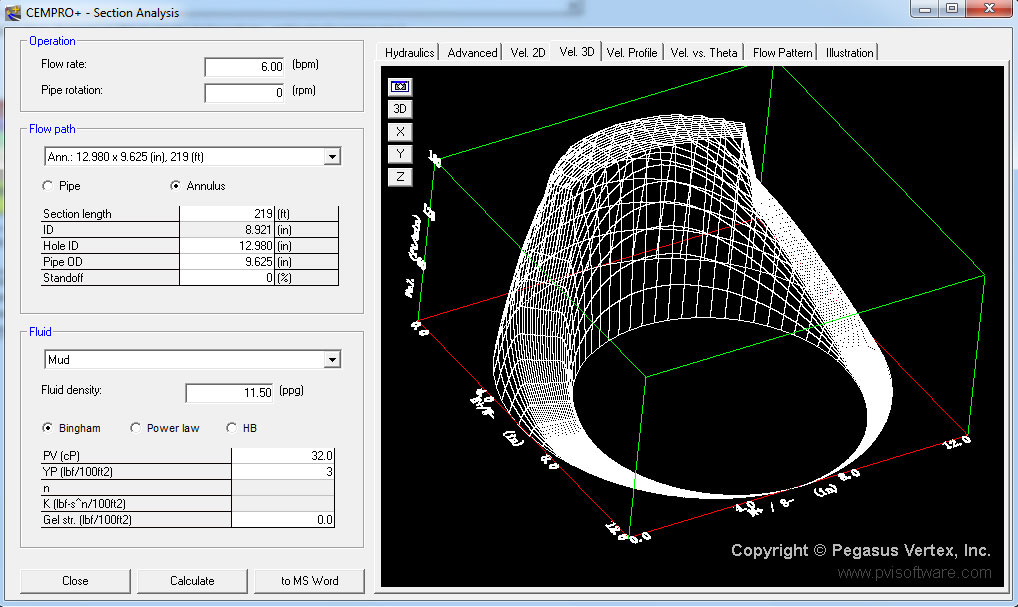

Designed for land, offshore, conventional and/or foamed operations, CEMPRO+ uses advanced numerical methods to solve momentum and continuity equations on 3D grids and calculates the fluid concentration as well as the displacement efficiency. It accounts for many factors that can affect the efficiency of displacement jobs, including fluid properties, pumping rates, casing standoff and complex wellbore geometry.

Although taking risks requires some blind trust in most cases, with a well done cementing job, drilling does not need to be a problem, but the complete opposite. We’ll never know what we can accomplish until we take the risks, and we can always get the best rewards by finding the right solutions or tools to keep the risks under control.