There are following methods to optimize blending formulation.

- Graphical Approach of IPT

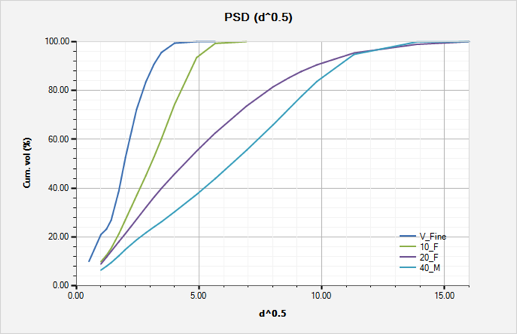

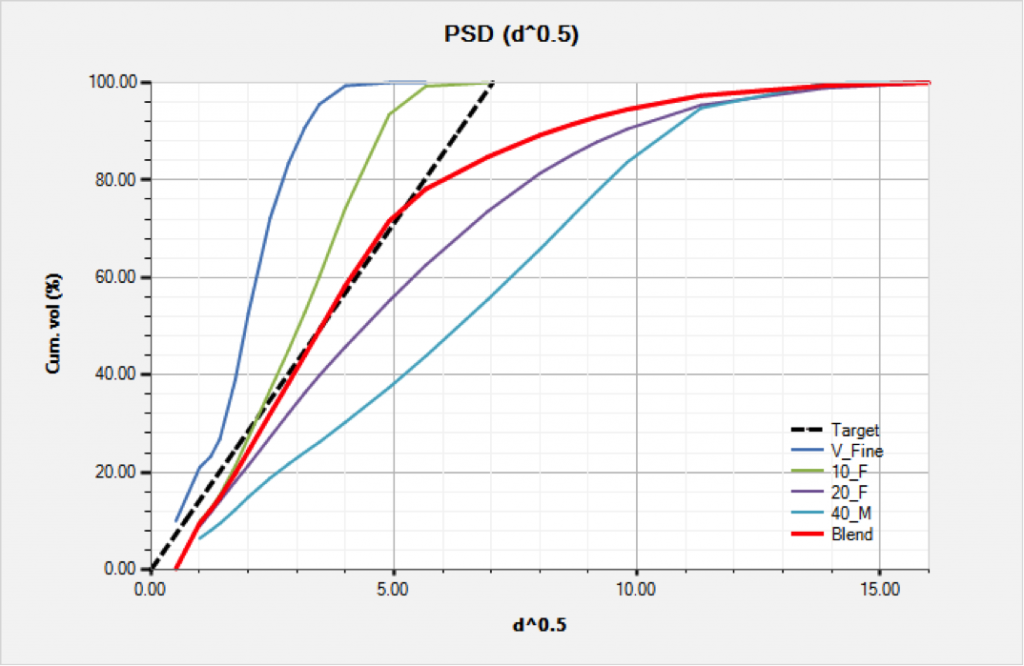

Dick [1] took a graphical approach to determine the optimum particle-size distribution of bridging material for the given formation characteristics. A wide range of commercially available bridging agents is plotted on the same graph utilizing the D1/2 rule as shown in Fig. 3. Although there is no single bridging agent that exactly matches the optimum target line, a more ideal formulation can be achieved by blending various sized-bridging agents to seal the targeted formation as shown in Fig. 4. - Optimum Target Line

An optimum target line based on formation information must be plotted before the optimum bridging agent blend can be determined. The design process normally starts with the “worst-case” possibility based on the largest dominant pore size or fracture width. The preferred method is to use pore sizing data from thin section analyses. However, if pore sizing data is not available then the formation permeability information can be used to determine the optimum target line.

Zhang [2] proposed methods for determining the optimum target line. His rule is:- Select the largest represented pore size from thin section analyses. This is the D90 point on the target line or 90% of cumulative volume shown in Fig. 2. D90 means 90% of the particles are smaller than size X. A straight line is then plotted by connecting the origin of Cartesian coordinate to the D90 point.

- If the pore size data is not available then the known permeability of the formation can also be used.

- If the maximum permeability is available then the maximum pore size D90 point can be estimated by taking the square root of the maximum permeability (in mDarcy).

- If the average permeability is known then the medium pore size D50 can be estimated by taking the square root of the average permeability (in mDarcy). The target line and the largest pore size D90 can be extrapolated by connecting the origin of Cartesian coordinate to the D50 point.

- Blend Line

Blending the proper ratio of bridging materials can help to obtain a more ideal formulation for sealing a given reservoir formation. The particle size distribution of the blend line should have a slope close to that of the optimum target line. The blend line is preferably slightly on the right side of the optimum target line. Experience [3] shows that this ideal formulation generally composed of three grades of bridging agents with different particle size as shown in Fig. 4. Calcium carbonate with a different particle size is commonly being used as bridging agents.

It has been found that 2-3% by volume (20-30 lb/bbl or 60-90 kg/m3) of a proper blend of bridging agents can provide an optimum seal on the face of permeable zones in clean fluids. In heavier weighted fluids, such as those containing barite, guidelines are more flexible with emphasis on larger diameter particles, recommend 3-5% by volume of properly sized solids. Yan [5] recommended the size of the coarse particles should be 4-5 times larger than the very fine particles in order to achieve the highest packing efficiency.

References

- SPE 58793, Optimizing the Selection of Bridging Particles for Reservoir Drilling Fluids M.A. Dick, T.J. Heinz and C.F. Svoboda, M-I L.L.C., and M. Aston, BP Amoco

- ZHANG Jin-bo,YAN Jie-nian. New theory and method for optimizing the particle size distribution of bridging agents in drilling fluids[J]. Acta Petrolei Sinica, 2004, 25(6): 88-91,95.

- SPE 104131, Design of Drill-in Fluids by Optimizing Selection of Bridging Particles, Yan Jienian, SPE, and Feng Wenqiang, China U. of Petroleum, Beijing

10099 Total Views 2 Views Today