There is an old joke in the real estate industry:

Question: “When establishing the value of a house, what are the 3 most important factors?”

Answer: “Location, location and location.”

In other words the area where the property is located is the one and only important matter and everything else you could say about it hardly matters.

This can be applied to a country as well. On my way back to Houston from a recent trip to Dubai I read an article about the upcoming world EXPO 2020, which will be hosted in Dubai. The article talks about the convenient location of Dubai. Two-thirds of the world’s population lives within an 8 hour flight from Dubai. No wonder Dubai’s international airport is as busy at night as it is during the day. My return flight from Dubai always leaves at around midnight, so that I can be either in Amsterdam or Paris in the morning to make my connection.

As the largest city in the UAE and the center point between Europe, Asia and Africa, Dubai has become a favorite city for the biggest headquarters of oil and gas, and service companies, including Russia’s Lukoil (oversea unit), and Halliburton among others.

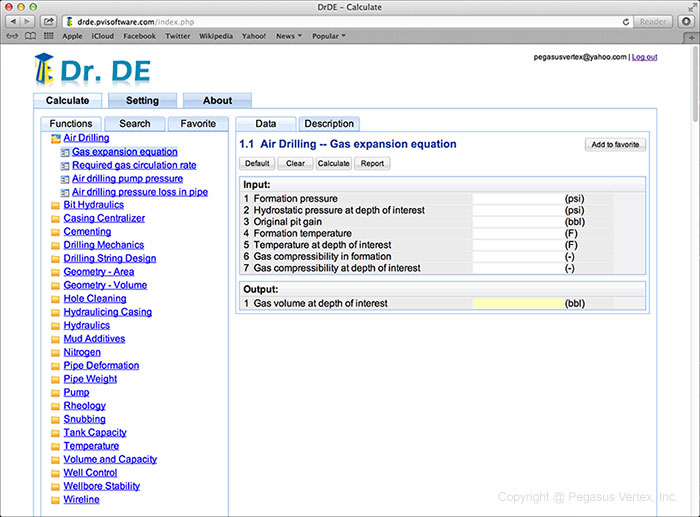

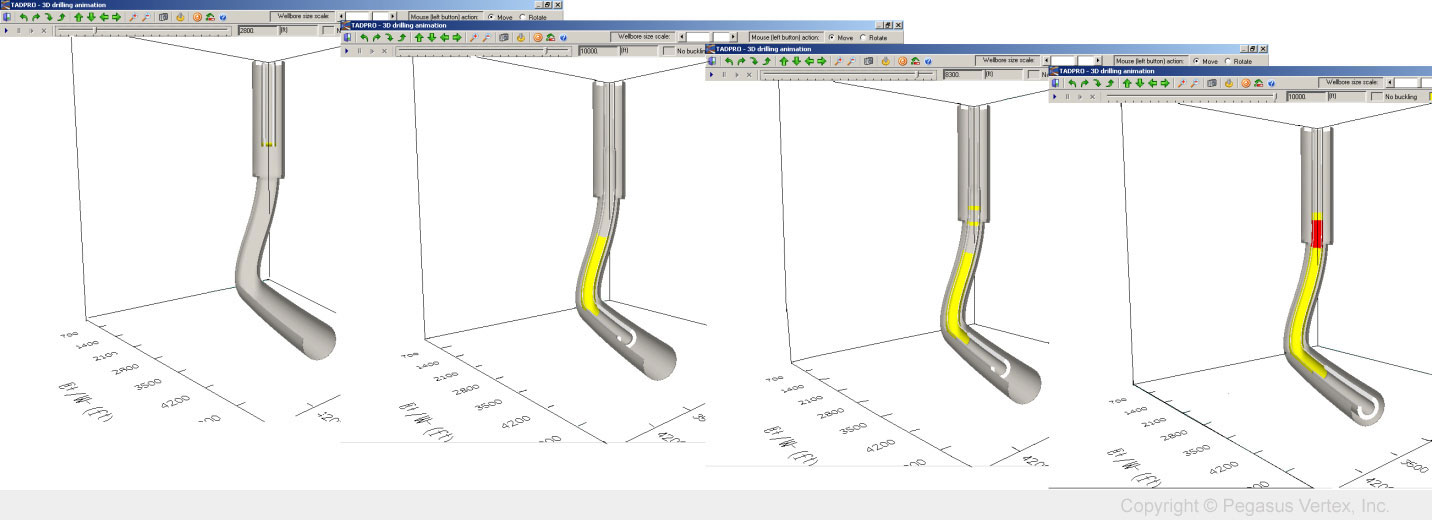

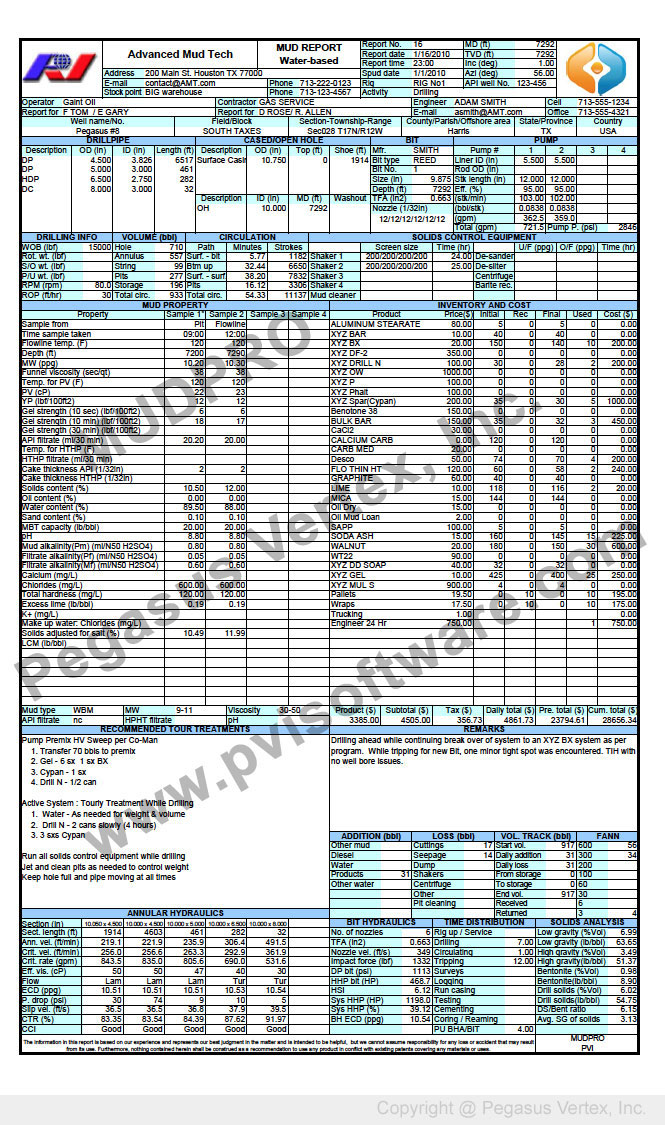

By comparison, Houston is the fourth largest city in the United States, well recognized worldwide for the energy industry. We are fortunate to live and work in this dynamic city from which we supply drilling engineering software and support our users.

Houston is an ideal location to support users in North America. It is also a gateway to many South American countries. It is said that over 90 languages are spoken in the Houston area. Our drilling software also “speaks” various languages for instance, English, Spanish, Russian, Chinese and Portuguese.

In spite of the hot summers, mild winters and occasional hurricanes, I do not have much to complain. Houston is a pretty good location for a drilling software provider like us.