Our industry is blessed with many talented and experienced engineers. We also have centralizer vendors producing the very best and top quality products. It is critical that we maximize the engineering potential while selecting the proper types of centralizers and placements. A software package like CentraDesign should be an integral part of the total approach of the centralizer placement optimization.

Theories and equations determining the casing deflection between centralizers are well established, even though a hand calculation for a deviated well is impractical.

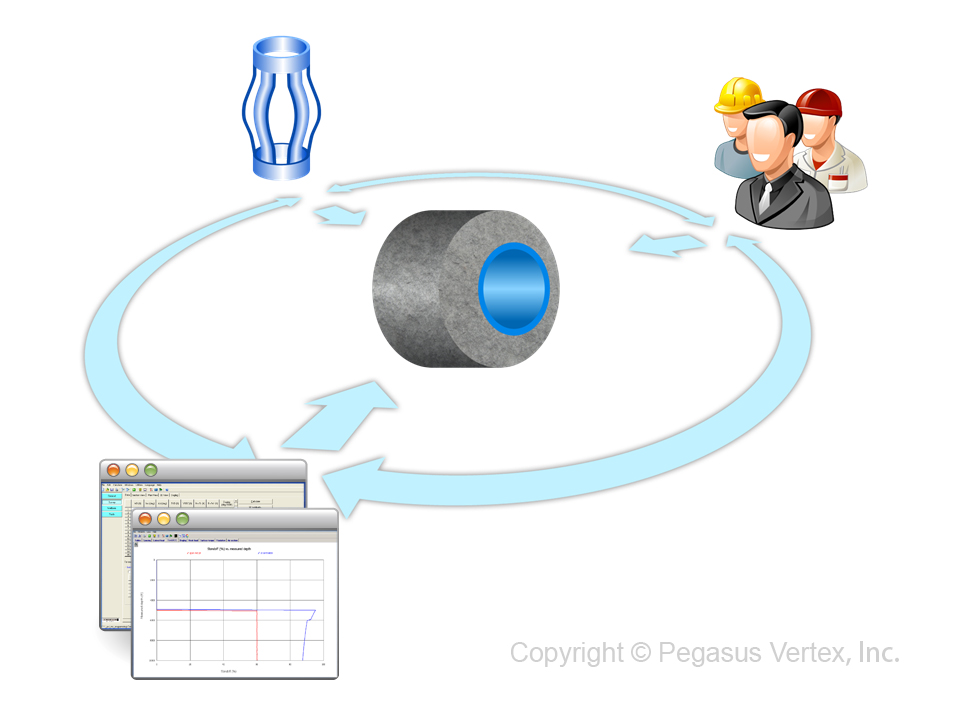

Experience plus software technology enable both centralizer vendors and operators to conduct centralizer optimization prior to field execution.

When optimizing the centralizer placement, consider the following:

- Each well is different. Our previous experience may not apply to the next well.

- Operators aim to obtain a satisfactory standoff with less centralizers.

- Similarly centralizer vendors aim to obtain a satisfactory standoff to sell more units.

- Software like CentraDesign optimizes the centralizer placement and usage.

- Computer modeling reduces risks and costs.

Centralizer placement can make or break a good cementing job. Computer modeling is not only an easy but also a necessary step to achieve optimization of centralizer usage. So, if you ask me the question: “Are we using too many or too few centralizers?” I would say: “If we all use readily available software to check the standoff profile for a specified spacing and optimize the placement, then we would probably use the correct number of centralizers.”