Computer casing wear modeling reduces risks and can identify potential problems prior to its occurring. Necessary modifications on casing designs and drilling parameters could be made before the pumping starts once we can predict the location and magnitude of wear.

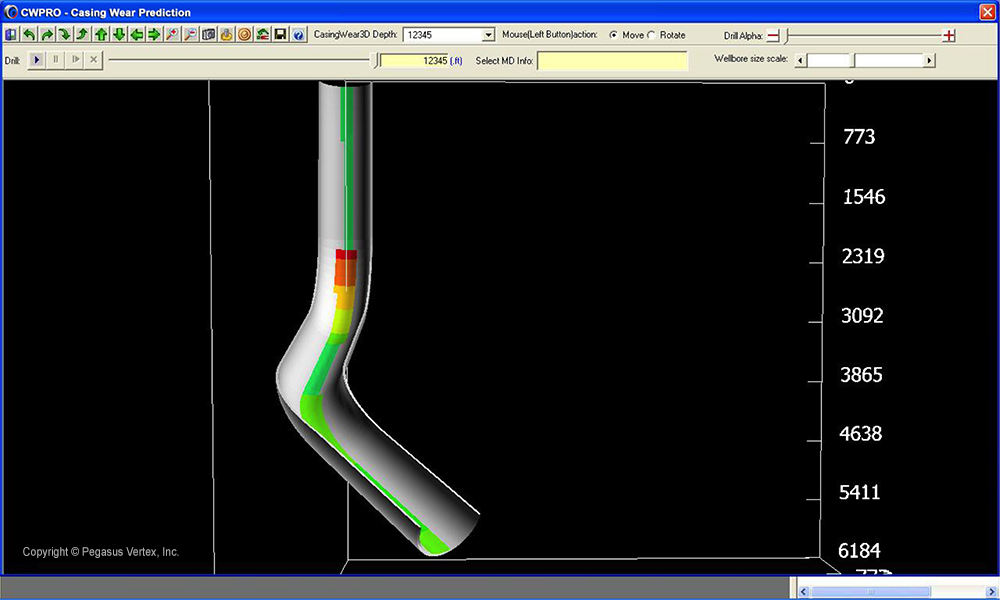

Figure 1 shows the 3D visualization of magnitude and location of wear in a previously set casing.

The knowledge we have acquired through decades of studies, lab testing, post-job analyses and computer modeling provides a good foundation for the following casing wear preventive measures:

- Minimize dogleg severity and expect real dogleg at least 1.5 times higher than the planned value.

- Use casing friendly tool joint materials.

- Reduce rotor speed and use downhole motor.

- Increase ROP.

- Select proper mud type and add lubricants to reduce wear and friction.

- Use drill pipe protectors.

- Use thick wall casing in the anticipated wear section area.

- Use software to reduce risks.

Please go to www.pvisoftware.com/white-paper/Casing-Wear-Causes-Prediction-and-Prevention.pdf to download the complete Casing Wear white paper.

8458 Total Views 3 Views Today