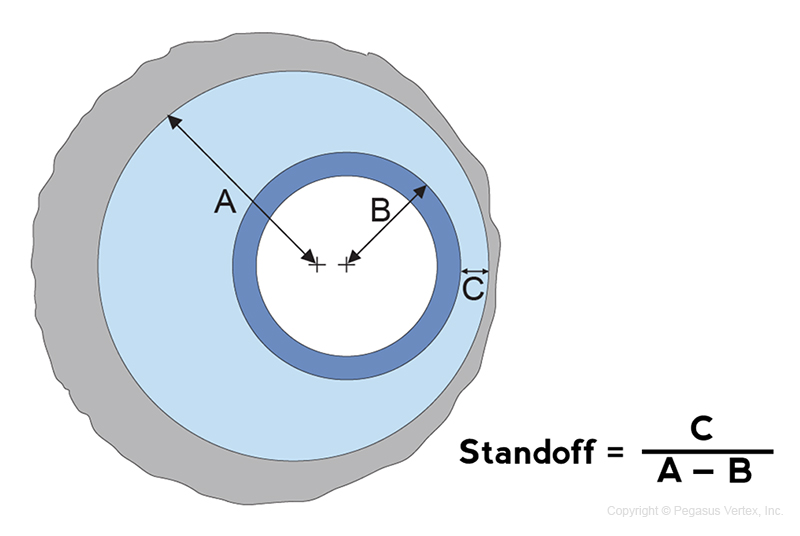

The term standoff (SO) describes the extent to which the pipe is centered (Fig. 1).

If a casing is perfectly centered, the standoff is 100%. A standoff of 0% means that the pipe touches the wellbore. Regardless of the centralizer type, the goal is to provide a positive standoff, preferably above 67%, throughout the casing string.

The casing deflection between centralizers obeys the laws of physics. An engineering analysis can help both operators and service companies arrive at the optimized number and placement of centralizers for a particular well.

The casing standoff depends on the following factors:

- Well path and hole size

- Casing OD and weight

- Centralizer properties

- Position and densities of mud and cement slurries (buoyance)

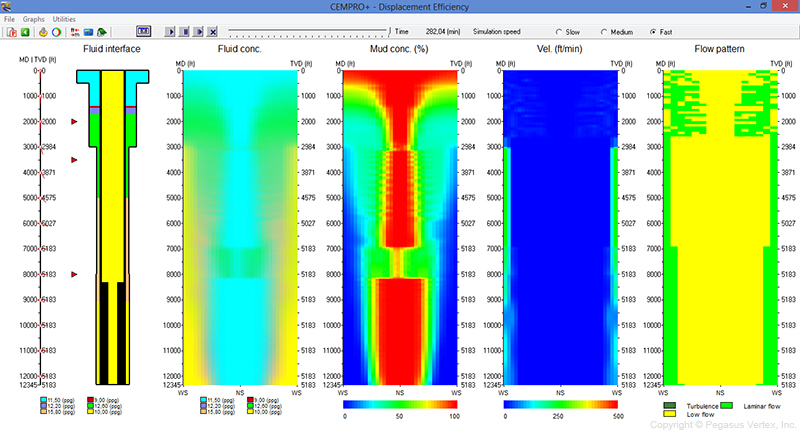

Incomplete mud removal causes poor cement seal and non-productive time. A good casing standoff helps reduce the mud channeling and improves the displacement efficiency. The following 2 pictures illustrate the impact of casing standoff on displacement efficiency. The 3rd track in Figure 3 shows the mud concentration in the annulus after a cementing job with 0% casing standoff.

You can see that there are some large red areas, which represent the high percentage of the remaining mud, in the narrow side (NS) of an eccentric annulus.

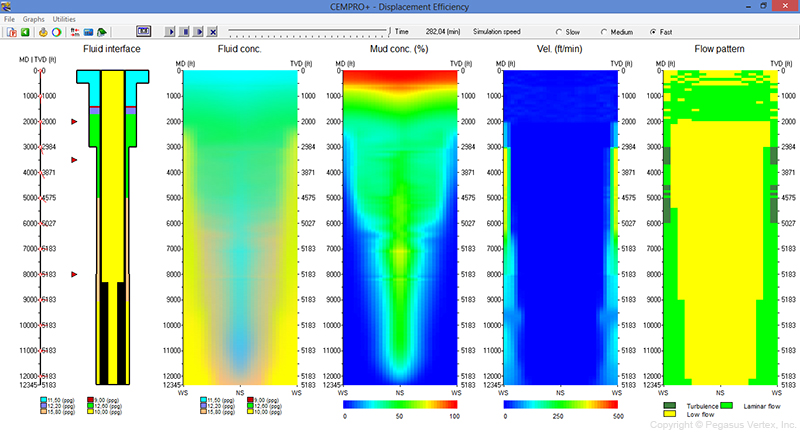

We kept everything else the same and only changed the casing standoff to 70%. Now the displacement efficiency improved significantly, as shown in the following picture.